Create

Commercialization, including scale-up, equipment specifications, production line installations, controls and automation, lean operational optimization, and construction management

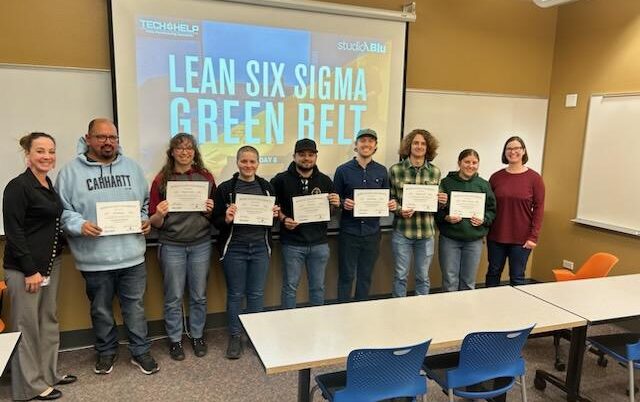

Engineering Innovation Studio

The Engineering Innovation Studio offers state-of-the-art technologies for product prototyping and process development in manufacturing. It fosters a hands-on learning environment for engineering students and professionals, focusing on designing for manufacturability. Our team supports projects in prototyping, technology validation, scale-up, automation, robotics, process optimization, and commercialization.

Equipment

Finishing

Dedicated paint booth

Polishing equipment

Sandblasting

Assembly benches

Woodworking/Plastics

Table saw

Scroll saw

Vertical band saw

Compound miter saw

Dust collection system

Nailers

fixturing station

Various hand tools

Production

2 drill press

horizontal bandsaw

3 vertical bandsaws

hydraulic press

belt sander

2 pedestal grinders

bench polishing and wire brush

wheel

arbor press

sheet metal shear

sheet metal brake

bead roller

pipe/tubing bender

various hand tools and handheld power tools

foam cutting hotwire

8 lathes (Jet, Monarch, Sharp, Red, Haas & Tida)

5 mills (Sharp manual and 2 Sharp CNC mills, 1 mini mill)

CNC & Hand-held plasma

Metal foundry

Forge

TIG welder

3 MIG welders

Arc welder

Handheld plasma

CNC Plasma oxy-acetylene

hot cut-off saw

grinders

Electronics workbench

Oscilloscope

Soldering irons

Power supplies

Signal generator

Wire supply station

Pre-Production

Group collaboration areas

Design software/display stations

6 Prusa 3D printers, including 1 Multi-color 3 Delta 3D printers, including 1 ceramic printer laser cutter/engraver

Want To Reach Out?

Contact the Engineering Innovation Lab Manager